What Gauge Wire For Solar Panels? Complete Guide 2022

Once you have decided to get energy-efficient in your life, your next step will be to install the correct items. The first step anyone usually takes is towards solar panels. Solar panels can be very challenging to install if you do not have the slightest clue about wire gauges.

What Gauge Wire Should You Use For Your Solar Panel?

There are a lot of steps in the process of wiring, but the most important one is the selection of the correct gauge. We know it must have your head spinning by now, so don’t worry; we have got you covered. So, what gauge wire should you be using for your solar panel anyway?

There is no specification for what gauge a wire must be unless the purpose and its connections are decided. Different gauge wires suit different requirements, therefore the same is the case with solar panels. Finding the right gauge is not as troublesome as it sounds.

Remember, if the wire is the correct gauge, it ensures safety and effortless operation. If the wire gauge doesn’t match the configuration, it could result in accidents. For example, you might have your entire roof on fire when it’s too hot outside. How can all of that happen, and what are the ways to avoid them? Read below.

Where did solar wire gauge even come from?

We know it’s many technical words that you weren’t expecting to hear when you decided to get energy efficient. But it is comprehensible, so here’s a quick guide. Solar wire gauge is the size of the wire that is needed to connect the elements of a solar panel system.

A solar panel constitutes various elements, including batteries, solar panels themselves, inverters, and charger controllers. To construct it for your use, you will need to wire these together to create a circuit.

Just like pipes, wires also help in conduction. The only difference is between water and electricity. Wires conduct current, so it flows to and from the components of a circuit. Wire gauges might vary according to their length and diameter.

If it’s a wire of a large diameter, the wire will offer less resistance. So, the current flow is safe and smooth. On the other hand, the flow will be impeded along with greater resistance if the diameter is small. Similar is the case with the length of the wire. There will be greater resistance if it’s too long and vice versa.

Remember these about the Solar Wire gauges

There is a standard scale for the gauges of solar wires, known as the AWG (American Wire Gauge). Wires come with different gauges and capacities. Whatever operation you seek from a wire, the gauge number will influence it.

So it is safe to say the higher you aim for the gauge number to be, the more resistance the wire will offer, and therefore the lesser will be the flow of current. Different usages will need different wire gauges. If you need it to be connected to the battery bank, the gauge might differ from charger controllers, etc.

The changes might also result because of the solar panel you are using. Commercial and residential both have different demands with it comes to wire gauges.

What is the ideal gauge of solar panel wires?

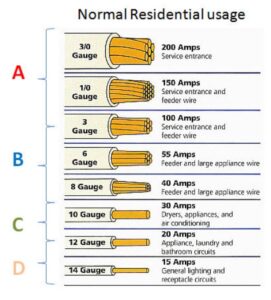

American Wire Gauge (AWG) is the average scale used for wires. The residential usage and gauge are readily available on the internet with correspondence to the amperes. But here are some examples to make the work easy for you:

- 14-gauge – provides 15 amperes that suit receptacle circuits and general lighting

- 12-gauge – provides 20 amperes that suit laundry and bathroom circuits and most appliances

- 10-gauge – provides 30 amperes that suit air conditioning, dryers, and appliances

- 8-gauge – provides 40 amperes that fit large wires for appliances and feeders

- 6-gauge – provides 55 amperes that suit large wires for appliances and feeders

- 3-gauge – provides 100 amperes that work for feeder wires and service entrances

- 1/0 gauge – provides 150 amperes that fit feeder wires and service entrances

- 3/0 gauge – provide 200 amperes that suit service entrances

Calculations for the components of a solar panel

The wire gauges used for solar panels depend on the voltage, voltage drop index, section load current, and length. No matter what component you aim to connect first, don’t forget to consider the points stated above.

It is well-known that the connection of the solar panels for commercial (above 50 watts), usually a 10-gauge wire is suitable. Concerning the gauges given above, 30 amperes correspond correctly with 10 watts. Therefore, a wire with a specific gauge that can easily let 30 amperes of current flow through the solar panels is ideal.

Now, many solar panels are wired parallelly, which requires a circuit that houses a larger gauge wire to form a combiner set. The wire gauge can then be finalized according to the number of panels you are attaching.

Usually, if you want the parallel network to work smooth and safe, pick between 8, 6, or 3-gauge wires and connect the panels to other elements of the circuit, e.g., the charger controller.

Moving on to the connection between the battery bank and the controller, the gauge selected is the same as the parallel circuit set. However, the exception lies with the combiner set voltages. If they are higher than the charger controller, the wire gauge must be large. Check this example for more clarification,

If the battery voltage of the charger controller is 12V or 24V, while the panels are working with a voltage that is higher than 48V – this creates an exception. There is a tendency for charger controller transformers to lower the voltage, due to which the current flowing towards the battery increases.

Moreover, the same is not the case with the battery bank wires. If the solar panel network requires two or more batteries, then there will be a need for their connection through the correct wire gauges. The battery bank also provides a connection for the inverter; the current should be enough for both charging and inverting. So, the current flowing in the wires of the battery bank gets the highest.

The best solution, in this case, is either the 3/0 or the 1/0-gauge wire so that the current provision will be between 150 to 200 amperes. Lastly, when you connect the inverter to multiple appliances, the wires needed are 14 and 12-gauges, providing less flow of current.

Connection of panels in Series-Parallel solar array

To know the wire gauge for a series-parallel array, two different wire gauge calculations will require, just like the one for a parallel array. The amperage and the voltage that flows through the wires before hitting the combiner vary differently from those out of the combiner. There is a need to find a selected wire size that suits each.

This means that when 5 amperes of current flow at 40 volts through a wire almost 20 ft from every panel in a series circuit, it is 10 ft away from the combiner. This allows a voltage drop up to 1.5% in the wire gauge calculator. Therefore, a 16-AWG wire will suit this circuit.

Through the combiner, now the parallel wired panels arrive in the circuit. Their amperages are added in the flow while the voltage for each remains the same. So the wires will now be providing ten amps through 20 ft wire at 40 volts, staying 10 ft away from the controller.

This will also allow the VDI to be 1.5% in the wire gauge calculator, so a wire with 14-AWG will be the best for this circuit.

Quick skim-through of the terms

Before calculating the current requirements and the flow characteristics of each component, there are specific terms that you need to know.

- Voltage:

Voltage is the difference of electric potential or the potential difference between two circuit ends when charged electrically. The representation for voltage is ‘V,’ and it is measured in Volts (V).

- Voltage Drop Index:

Undersized wires can reduce the voltage that leads to a drop of voltage in that wire, which ultimately causes power loss. The index used to measure this drop is the voltage drop index (VDI).

- Current:

The flow of electrons in the electrical circuits mimicking water flow in a cylindrical tube is known as current. Formula term for current is ‘I.’ as it is the flow rate of charges, so it is measured in amperes (amps).

Length calculations of the wire

By now, we know that a small wire results in a voltage drop resulting in severe power loss. Not only that, but the length of the wire can also change the solar panel performance. The more the length of the wire, the higher its resistance will be, so there are chances of high voltage drop. Therefore, the calculations of wire gauge requirements are necessary.

The longest wire of all the component connections is between the charger controller and the array of panels. Therefore, you need wires with the correct length and gauge, so the flow is smooth and safe. The formula for the calculation of voltage drop index is:

VDI = (Amps x Ft.) / (V Drop % x V)

This formula can be expanded as,

Amp is the current of the set of wires

Ft is the required length of the wire

V Drop % is the VDI

V is the voltage of the given wire

(It is important to note that most users agree for the regular VDI to stay less than 2%)

Furthermore, you need first to calculate or find the values required, then proceed to the length of the wire. The gauges of wires decide the voltage and current. Any ups and downs in the calculation can have harmful results and may lead to short circuits. To avoid any such circumstances, it is necessary to do your proper research before aligning a circuit and plugging it in. To be in the safe zone, check with a specialist.

Conclusion

It can be concluded that when the requirement of usage is not only the energy efficiency but also safety, the solar panel wires should be wired correctly. It is essential to arrange the solar panel wires perfectly at the correct gauges. During the selection process, you have to be keen about calculating gauges as per the criteria we described above.

Doing your research is always a smart move if you have already decided to be productive and play your part in safe energy consumption. This article was written to provide information about the detail of the wires’ dimensions, length, and gauges.

We understand that the need for every user of solar panels is different. No matter if you use them generally or commercially, know your wires. It is essential for arrangement and subsequent working criteria and the safety of your building.